There are two general types of acetal resins available: acetal homopolymer and acetal copolymers. Each type of acetal has its own set of advantages and disadvantages. Acetal (polyoxymethylene, POM) is a thermoplastic polymer commercialized in the early 1960’s. This material is produced through the polymerization of formaldehyde.

Acetal homopolymer resins are currently made by the DuPont Company under the trade name Delrin®.

Acetal Homopolymer offers the following benefits:

- Stiffer than acetal copolymers. Higher flexural modulus at room temperature and elevated temperature applications.

- Higher impact strengths at room temperatures and low temperatures.

- Tensile strength is approximately 10 – 15% higher than comparable copolymers.

- Slightly higher continuous use temperature than copolymer (95C vs. 90C).

Acetal copolymer (TECAFORM AH™) This material, on the other hand, has the following advantages over Homopolymer:

- Improved dimensional stability over comparable homopolymer formulations due to its lower level of crystallinity.

- Better chemical resistance with high pH (basic) solutions.

- Lower centerline porosity than homopolymer in extruded shapes.

In most cases, acetal homopolymer and copolymer can be interchanged because many material properties are approximately 10 % of each other. Typical physical properties are shown in the accompanying table.

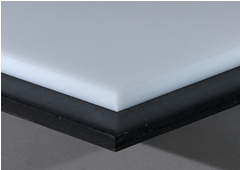

Perhaps the most significant difference between homopolymer and copolymer acetal relates to the phenomenon known as “centerline porosity”. It is most prominent in extruded parts, particularly thick

slab and large diameter rod stock. Visually, it is a whiter shaded region around the center portion of a rod, which extends down the entire length. In slab, porosity appears as a line along the center of each cut edge.

In some cases, the slab may appear to be laminated or glued together. Excessive centerline porosity is undesirable for the following reasons:

- Cosmetic – inconsistent color appearance in finished parts.

- Compromises structural integrity

- Present routes for leakage of gas and liquids.

- Provide areas where bacteria can grow in food processing applications.

The major cause of porosity is shrinkage. During the extrusion process, the outside skin of the shape cools before the interior region. As the interior material cools, there is a corresponding reduction of

volume. Since the overall volume change of the shape is restricted due to the solidified skin, voids form to compensate for the loss of interior volume.

Delrin® is a registered trademark of E. I. DuPont de Nemours Co., Inc.

TECAFORM™ = Ensinger Industries Inc.

Modern Plastics Distributes Ensinger Acetal Products

Contact: Modern Plastics, 88 Long Hill Cross Road, Shelton, Connecticut 06484 USA

Email: sales@modernplastics.com Phone: (203) 333-3128 Fax: (203) 333-4625

0 Comments