by Bing Carbone

Automotive technology is increasing at lighting speed, with new materials being applied every year that increase durability, longevity and wear. These materials allow cars to resist wear and damage, and to last longer than ever before. One of these materials is Ensinger Delrin acetal resin. Here’s a look at the properties of Delrin and why it is a great material for automotive applications.

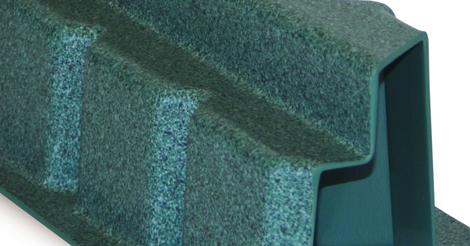

Delrin Homopolymer

Delrin acetal resin is a crystalline plastic material which can bridge the gap between metal and plastic. It has a very high tensile strength and great toughness and creep resistance. It has a very low moisture absorption and is highly resistant to solvents, neutral chemicals and hydrocarbons. These core properties of the material make it ideal for a broad variety of applications.

Some of the most important features of Delrin are its dimensional stability, high degree of machinability, endurance against fatigue and heat, and wear/abrasion properties. Its natural grade is comprised of FDA, NSF and USDA-compliant resin, making it very safe for use.

Automotive Applications

Its heat resistance and ability to maintain tolerance in the face of temperature swings make Delrin an ideal material for automotive applications. It has just the right wear resistance and dimensional stability for a broad range of components applications from automated paint systems and curing ovens as well as basic accessories like windshield wipers.

General Components

It can be applied to a variety of pump and valve components that will be exposed to high heat or extreme moisture as well as a broad variety of brushings, rollers, bearings, gears, electrical insulation parts and fittings that can be used throughout the body of an automobile, even in areas where previously only metal parts would suffice. Delrin has the ability to replace metal in an economical, yet dependable, fashion.

Vehicle Interiors

The automotive industry has very exacting and demanding requirements regarding plastics that can be used for vehicle interiors, and Delrin meets all of these requirements. This makes it ideal for situations where high-impact load resistance is indicated, from large and visible parts to small levers and gears, as well as in seating areas of cars.

Always Improving

The latest versions of this plastic are even more impact resistant than prior creations. With its easy machinability combined with high resistance to impact, vehicle trims of all shapes, sizes and varieties can be constructed using Delrin homopolymer plastics. One of the major uses for this material is for headrest struts, but parts of all shapes and sizes will be constructed from Delrin in the future.

For decades, automotive manufacturers have been looking for ideal materials to use in their vehicles. Delrin acetal resin has a crystalline structure whose resistance to chemicals, heat and temperature variations as well as its impact resistance and ease of machinability make it the solution for which the industry has been searching. Modern Plastics is proud to have partnered with Ensinger to bring Delrin plastics to our customers. Read a bit more about Delrin acetal resin and get in touch with us to place your order today!