In the food industry, choosing the right materials is critical—not just for performance, but for safety and compliance. At Modern Plastics, we supply food-grade engineering plastics that meet FDA, USDA, and EU regulations while performing reliably in food processing and packaging environments.

Why Use Food-Grade Engineering Plastics?

Food processing machinery operates in demanding conditions—moisture, high heat, pressure, and chemical washdowns. That’s why processors rely on engineering plastics such as Acetal (POM), PEEK, PVDF, PET, PBT, and Nylon. These food-grade materials combine high performance with safety and durability.

👉 Explore our full line of engineering materials »

Top Food-Grade Plastics and Their Common Applications

Acetal (POM)

-

Low moisture absorption, high dimensional stability

-

Ideal for cams, gears, and star wheels

-

Fully FDA-compliant

PEEK

-

Heat-resistant up to 480°F

-

Excellent chemical resistance for high-load and hot zones

PVDF

-

FDA-grade material for caustic washdown areas

-

Superior chemical and UV resistance

PET & PBT

-

Tough, dimensionally stable, and moisture-resistant

-

Used in packaging machinery and flow-control parts

Nylon

-

Strong, versatile, and available in metal- and x-ray-detectable grades

-

Common for scrapers, bushings, pulleys

Ultra-Detectable Plastics for Food Safety

Modern Plastics offers detectable food-grade engineering plastics that help prevent contamination by being:

-

X-ray detectable

-

Metal detectable

-

Magnetically detectable

-

Color-contrasting (typically blue or red for visual inspection)

These materials are used in parts such as scrapers, feed screws, guards, and metering nozzles—making it easy to identify fragments before they reach the consumer.

👉 Learn more about our detectable materials »

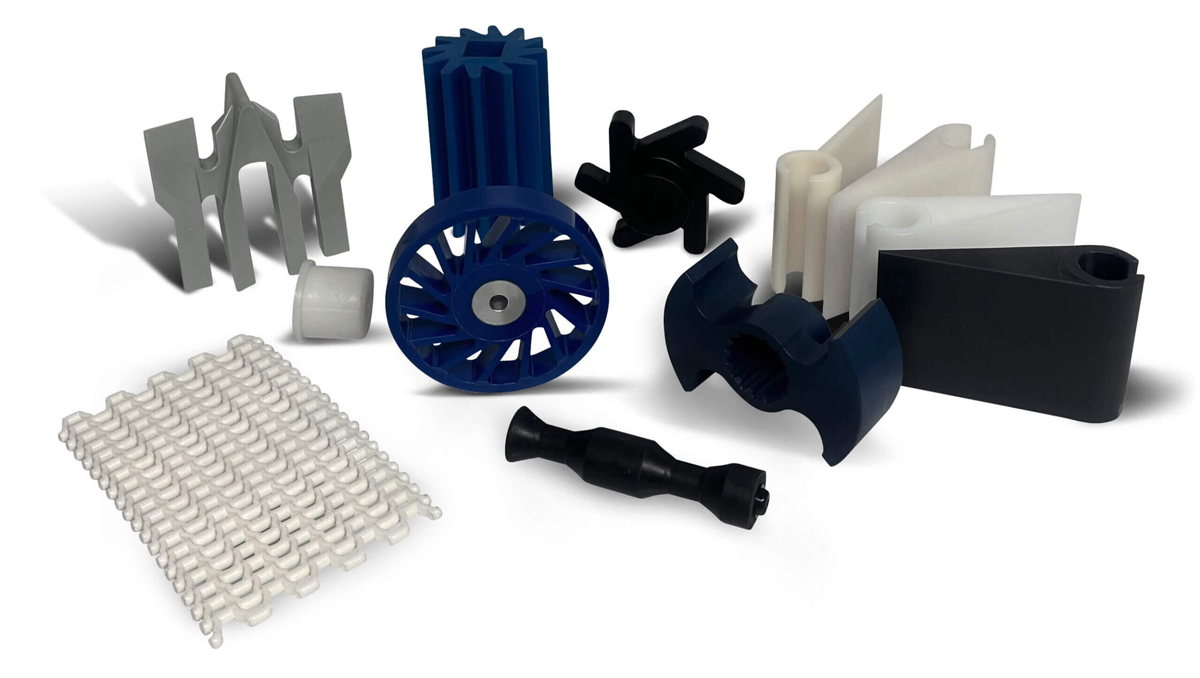

Common Applications in Food Equipment

-

Scrapers & Deflectors

-

Pulleys & Star Wheels

-

Metering Nozzles & Guides

-

Bushings & Cams

-

Conveyor Rollers & Guards

These components benefit from lightweight, corrosion-resistant, low-friction plastics that reduce maintenance and increase equipment longevity.

Why Food Processors Choose Modern Plastics

Modern Plastics provides high-performance food-grade engineering plastics in rod, sheet, or custom-machined formats. Our materials help processors:

-

Meet FDA, USDA, and EU compliance

-

Reduce contamination risk

-

Improve efficiency and uptime

-

Maintain long-term part durability

From prototyping to production, we help OEMs and food manufacturers get the exact materials they need—cut to size, machined to spec, and ready to perform.

👉 Request a quote or contact our experts to get started.

0 Comments