by Bing Carbone

Custom Plastic Fabrication

The custom plastic fabrication field is plagued by counterfeit materials, which makes it vital to use an expert and experienced service. These qualified producers of custom plastic materials know how important it is to use the right materials for the right processes.

Using the wrong plastic can not only lead to poor quality parts, in some cases it can create disastrous situations when a machine or equipment piece catastrophically fails. Here is a primer of some of the common and important kinds of plastics and what products they best serve.

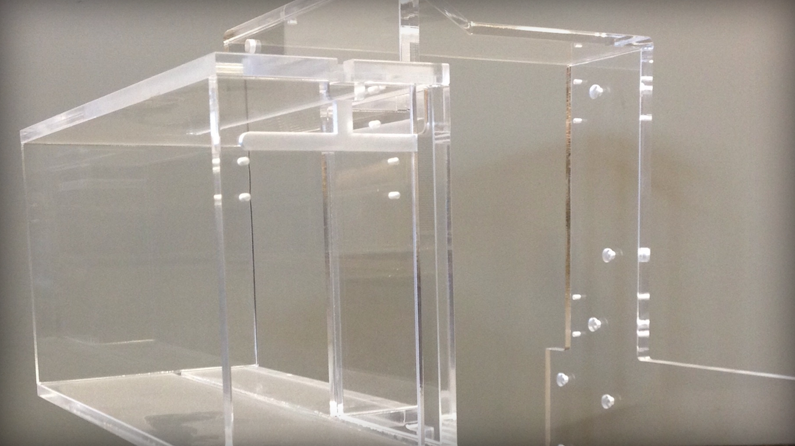

Acrylic Sheeting

Acrylic sheeting is one of the most versatile and common forms of plastic available in the market. It comes in a wide variety of colors, shades and clear finishes and is produced by many household-name brands such as Lucite®, Plexiglas®, Acrylite® and more. When you are looking for good optix, light weight and strength as well as versatility, acrylic is an excellent choice.

Acrylic Rods

Acrylic rods are strong, light and durable. They are easily fabricated, bonded and bent to take on a variety of shapes and forms. As with sheeting, they can come in a clear finish or a broad variety of solid or translucent colors. They can be produced using a casting process or through extrusion.

Acrylonitrile Butadiene Styrene (ABS)

ABS comes in sheet or rod forms and is one of the most versatile and adaptable plastics out there. It is easily vacuum formed or can be shaped, bent, machined and bonded to just about any form desired. It is water and impact resistant and very rigid. This plastic is often used in prototyping because of its low cost and ease of shaping.

Polycarbonate

One of the toughest plastics out there, polycarbonate is gorgeous, impact-resistant and very versatile as well as being an ideal material for machining and forming. It is available in a variety of sheets, plates, rods, tubes or film and can be coated for abrasion resistance, non-glare, and static dissipation.

Polyvinylchloride (PVC)

Everyone has heard of PVC in terms of plumbing — it is one of the most popular materials for pipes there is. It is very lightweight and inexpensive, and it’s as tough as it is light. It is resistant to corrosion and takes well to insulation. It is also available in many colors, weights and sizes and can be easily machined and heat formed. PVC can also be providing in sheet, rod, tube and a variety of shapes.

Styrene

Styrene is often used as a lower-cost alternative to ABS when it comes to prototyping. It is impact resistant, food safe and comes in a variety of grades. This plastic is lightweight and very versatile, being easily machineable and formable. Styrene is a popular component in many industrial applications.

Polytetrafluoroethylene (PTFE)

PTFE is more popularly known by its brand name: Teflon®. Made by DuPont, this plastic is best known for its non-stick properties but it is easy to machine, low friction, and non-reactive. Besides its common use in cookware, it is ideal for machine parts where high heat, chemical resistance and electrical insulation are required.

Modern Plastics offers over 300 types of commodity and engineering plastic for industrial, chemical, construction, defense, electronics, energy, food processing, lighting marine, medical, OEM, pharmaceutical, semiconductor, transportation, waste water, and wood & pulp. To determine which material is right for your application, contact any of our customer service representatives at 800-243-9696.

Take a look at the products we offer, and give us a call for more information today!