High Performance Medical Grade Plastics for the Medical Device Industry

Table Of Contents

Plastics for medical devices

Plastics used in medical industry

Why Trust Modern Plastics?

Plastics For Medical Devices

One of the largest distributors in the United States, Modern Plastics provides high performance medical grade polymer/plastics stock shapes to the medical industry. These industries use these plastics for medical devices.

We serve a wide range of medical markets with medical plastics and have compiled this list to inform you on the various biocompatible, FDA-approved medical grade plastics we use to serve the medical device industry.

If you have a question about any of the medical plastics mentioned, our experts will be happy to assist you – contact us here or tap Interested in Our Services to email or text us at any time.

Plastics Used In Medical Industry

Why Trust Modern Plastics?

Modern Plastics has led by setting new industry standards throughout its 75 years in plastics distribution.

Modern Plastics is an ISO-Certified company (9001:2015 and AS9120B, 9001:2015 and AS9100D & 13485:2016) with a large inventory of medical polymers compliant to FDA, ASTM, USP VI, and ISO 10993 specifications.

Our experienced Sales & Quality staff have over 25 years of experience servicing the medical device industry.

We inventory medical grade plastics that are lot controlled, individually line marked and bar-coded for complete material traceability.

Learn more about our services here.

Acetal Copolymer (POM-C)

Material Overview: POM-C

POM-C material, commonly called Acetal Copolymer (chemically known as Polyoxymethylene) is a medical grade plastic manufactured in standard stock shapes for machining and is extruded in sheet, rod and tube.

POM-C plastic is a highly crystalline thermoplastic with high mechanical strength, rigidity & dimensional stability.

Acetal polymer has good sliding characteristics and excellent wear resistance, as well as low moisture absorption.

The good dimensional stability and particularly good fatigue strength, as well as excellent machining ability, makes POM-C polymer a highly versatile engineering material, even for complex components.

POM-C for Medical Use

Acetal Copolymer (POM-C) material is resistant to multiple cleaning and disinfection agents, and to a number of solvents.

It can be steam sterilized by medical industry’s usual methods, and will maintain good strength, stiffness, and dimensional stability.

It is tested for biological compatibility on the stock shape and can be supplied in a variety of different colors and dimensions.

Medical Market Usage

The following medical markets use Acetal Copolymer (POM-C): Spine, Sports Medicine, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Acetal Copolymer (POM-C) from are listed along with the trade names they use:

Acrylic (PMMA)

Material Overview

Acrylic, the common name for polymethyl methacrylate (PMMA), is a medical grade plastic that has long been used in the manufacture of medical devices & medical implants such as intraocular lens implants, bone cement, cranial implants & medical devices requiring impact strength, chemical resistance, biocompatibility, and clarity.

Optical clarity is an important quality in medical devices or diagnostic equipment that rely on visual inspection and therefore require a high level of transparency.

Medical Market Usage

The following medical markets use Acrylic (PMMA): Cranial, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The supplier we source Acrylic (PMMA) from are listed along with the trade names they use:

- Spartech Polycast Medical Grade PMMA

Polycarbonate (PC)

Material Overview

Polycarbonate plastic (PC) is an amorphous thermoplastic with good electrical properties combined with superior impact strength, toughness and moderate chemical resistance.

Due to its low crystallinity and amorphous nature, PC has a high level of transparency.

Polycarbonate medical grade plastic sheet, rod and tube meet the stringent performance characteristics and requirements of the healthcare industry. Suitable for ETO Gas & limited autoclaving sterilization.

Some polycarbonates such as Zelux GS have proprietary color enhancement technology to reduce color shift caused by gamma radiation.

Polycarbonate manufacturers tend to offer their polycarbonate material in the mid-price range which makes it a very versatile material choice for a number of medical application uses.

Medical Market Usage

The following medical markets use Polycarbonate (PC): Medical Device, Drug Delivery, Pharmaceutical, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polycarbonate (PC) from are listed along with the trade names they use:

- Westlake Plastics ZELUX (GS) (PC)

- Ensinger TECANAT (PC)

- Rochling SUSTANAT (PC)

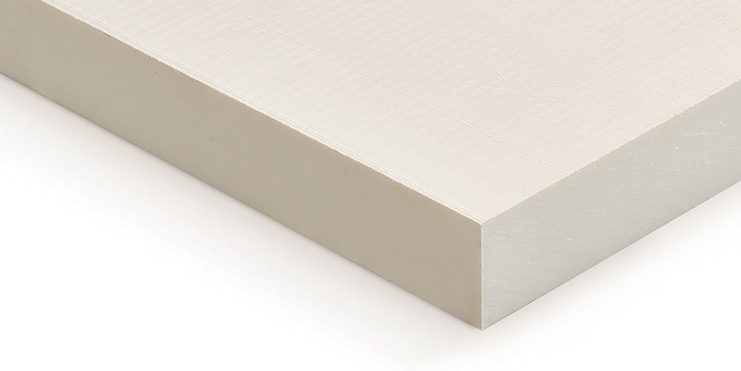

Polyether Ether Ketone (PEEK)

Material Overview

Polyether Ether Ketone (PEEK) is a unique semi crystalline, engineering thermoplastic that also offers excellent chemical compatibility, low susceptibility to stress cracking, clinically proven biocompatibility, high dimensional stability, good electrical insulation & it is easy to machine.

Parts manufactured from high temperature medical grade plastic PEEK polymer can also operate at temperatures up to 260°C (480°F) and have a melting point around 341°C (646°F).

PEEK is used in medical products to improve their usefulness. PEEK has excellent mechanical strength and impact properties.

It also has good dimensional stability and can be sterilized via steam autoclave, EtO gas and or conventional gamma radiation.

Experienced users have come to realize the added value that PEEK materials bring, by offering the possibility of manufacturing parts that are lighter, stronger and able to survive longer in harsh environments.

Medical Market Usage

The following medical markets use Polyether Ether Ketone (PEEK): Spine, Sports Medicine, Cranial, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polyether Ether Ketone (PEEK) from are listed along with the trade names they use:

- Ensinger TECAPEEK

- Evonik VESTAKEEP PEEK

- Rochling SUSTAPEEK

- Quadrant KETRON

Polypropylene (PP)

Material Overview

Polypropylene (PP) is a semi crystalline thermoplastic manufactured by the catalytic polymerization of propene.

Polypropylenes are universal standard medical grade plastics with well-balanced properties, providing excellent chemical resistance, high purity, low water absorption and good electrical insulating properties.

Special medical grades of polypropylenes offer heat stabilization for use in higher temperatures.

Medical grade polypropylenes also offer excellent dimensional stability, machinability and the ability to withstand sterilization from “steam” autoclaving.

Medical Market Usage

The following medical markets use Polypropylene (PP): Spine, Sports Medicine, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polypropylene (PP) from are listed along with the trade names they use:

- Ensinger TECAPRO MT

- Westlake Plastics PROPYLUX

- Rochling POLYSTONE® P

Polyphenylsulfone (PPSU) – Radel®

Material Overview

Polyphenylsulfone (PPSU) is an amorphous material, which has a high glass transition temperature and low moisture absorption.

Medical grade plastic Radel (PPSU) stock shapes offer exceptional hydrolytic stability, toughness, and superior impact strength over a wide temperature range.

This product also offers high deflection temperatures and outstanding resistance to environmental stress cracking. Recommended sterilization techniques for Radel R5500 include ETO gas, radiation, steam autoclaving, dry heat and cold sterilization.

Medical Market Usage

The following medical markets use Polyphenylsulfone (PPSU): Spine, Sports Medicine, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polyphenylsulfone (PPSU) from are listed along with the trade names they use:

- Rochling SUSTASON PPSU RADEL R

- Ensinger TECASON P + RADEL R

- Westlake Plastics RADEL (R5500)

- Quadrant PPSU RADEL R

Ultra-High Molecular Weight PE (UHMW-PE)

Material Overview

Polyethylene (PE) polymers are semi crystalline thermoplastics with a high degree of toughness and very good chemical resistance.

Medical & implantable Ultra-High Molecular Weight Polyethylene (UHMW-PE) is a medical grade plastic with high impact strength, good wear/abrasion resistance, excellent chemical resistance and outstanding low temperature properties.

Medical & implantable UHMW per ASTM F648 is produced from premium resin and international ISO standards for surgical implants & medical devices.

Recommended sterilization techniques for UHMW include ETO gas, cold sterilization, and limited gamma irradiation.

Medical Market Usage

The following medical markets use Ultra-High Molecular Weight Polyethylene (UHMW-PE): Sports Medicine, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Ultra-High Molecular Weight Polyethylene (UHMW-PE) from are listed along with the trade names they use:

Polytetrafluoroethylene (PTFE) – Teflon®

Material Overview

Polytetrafluoroethylene (PTFE), colloquially referred to as Teflon®, is a semi crystalline fluoropolymer with many unique characteristics.

This fluoropolymer has unusually high thermal stability and chemical resistance, as well as a high melting point that ranges from -200 to +260°C (-328 to +500°F) and can sustain short-term up to 300°C (572°F).

In order to improve the mechanical properties, PTFE plastics can be reinforced with additives such as glass fibre, carbon or bronze.

In addition, PTFE products are self-lubricating with a low friction coefficient, excellent electrical resistance and a non stick surface.

Medical grade plastic PTFE stock shapes are available (Rod & Plate) per USP Class VI.

Medical Market Usage

The following medical markets use Polytetrafluoroethylene (PTFE): Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Polysulfone (PSU)

Material Overview

Polysulfone (PSU) is a high temperature medical grade plastic with high mechanical strength and rigidity.

Apart from the high continuous use temperature, the outstanding characteristics of the material include good creep strength that is remarkably high over a wide range of temperatures.

PSU also has excellent dimensional stability, very good resistance to hydrolysis and good chemical compatibility.

Medical Market Usage

The following medical markets use Polysulfone (PSU): Spine, Sports Medicine, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polysulfone (PSU) from are listed along with the trade names they use:

- Westlake Plastics THERMALUX (PSU)

- Ensinger TECASON S (PSU)

- Rochling SUSTASON (PSU)

Polyphenylen Sulfide (PPS)

Material Overview

Polyphenylen Sulfide (PPS) medical grade plastic is a semi crystalline, high temperature thermoplastic polymer.

Due to its structure, PPS is a very chemically resistant polymer with amazing mechanical strength, even at temperatures above 200°C (392°F), very stable dimensionally with low susceptibility to creep.

In addition to its low water absorption, PPS polymer also has good dimensional stability and excellent electrical properties.

Medical Market Usage

The following medical markets use Polyphenylen Sulfide (PPS): Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polyphenylen Sulfide (PPS) from are listed along with the trade names they use:

- Westlake Arolux (PPS)

- Ensinger TECATRON (PPS)

- Rochling SUSTATRON (PPS)

- Quadrant TECHTRON (PPS)

- Solvay Ryton (PPS)

Polyvinylidene fluoride (PVDF) – Kynar®

Material Overview

Polyvinylidene fluoride (PVDF) is an opaque, semi crystalline, thermoplastic fluoropolymer.

PVDF is characterised by excellent chemical resistance without having the disadvantages of low mechanical values and/or processing difficulties which can be experienced with other fluoroplastics.

Medical grade plastic PVDF shows a melting point of 171°C (339°F).

Medical Market Usage

The following medical markets use Polyvinylidene fluoride (PVDF): Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polyvinylidene fluoride (PVDF) from are listed along with the trade names they use:

- Westlake Plastics PVDF Kynar® 740

- Ensinger TECAFLON PVDF

- Rochling POLYSTONE PVDF + SUSTA PVDF

- Simona America SIMONA® PVDF

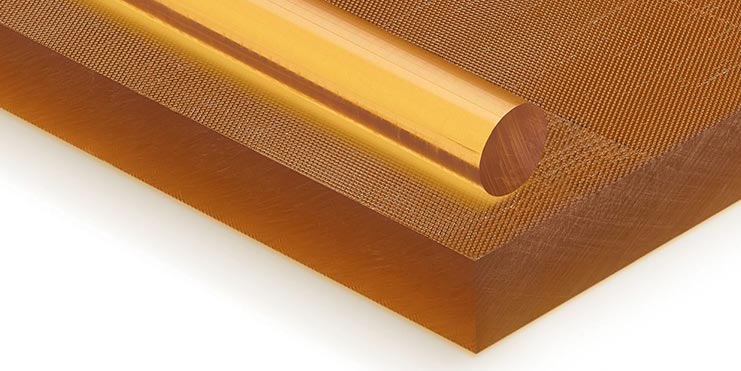

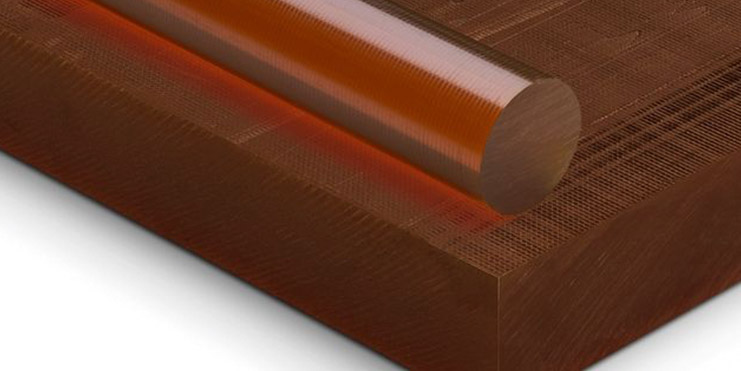

Polyetherimide (PEI) – Ultem®

Material Overview

Polyetherimide (PEI) material is an amorphous thermoplastic with high mechanical strength and rigidity.

Unfilled PEI thermoplastic is translucent and amber in color with exceptional mechanical, thermal and electrical properties.

In filled grades, the addition of glass fiber reinforcement provides users with a polyetherimide offering that has both greater tensile strength and rigidity, while also improving dimensional stability.

PEI Ultem® medical grade plastic has a remarkably high creep resistance over a wide temperature and a high permanent operating temperature.

Furthermore, impressive resistance to hydrolysis, along with dimensional stability rounds out the portfolio of polyetherimide properties.

Medical grade Ultem® is available in a wide range of colored stock shapes and can withstand sterilization techniques including ETO Gas, radiation, steam autoclaving, dry heat & cold sterilization.

Medical Market Usage

The following medical markets use Polyetherimide (PEI): Spine, Sports Medicine, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polyetherimide (PEI) from are listed along with the trade names they use:

- Ensinger TECAPEI (PEI)

- Rochling SUSTAPEI (PEI)

- Westlake Plastics TEMPALUX (PEI)

Polyphenylene Oxide (PPO) – Noryl®

Material Overview

Polyphenylene Oxide (PPO) Noryl® is a strong medical grade plastic with outstanding mechanical, thermal and electrical properties.

Very low moisture absorption and low thermal expansion make Noryl® one of the most dimensionally stable thermoplastics available.

Noryl® is widely used for electrical housings and structural components since it has excellent insulating properties, flame resistance, and dimensional stability over a wide range of service temperatures.

Noryl® is often selected for fluid handling applications since it has low moisture absorption and excellent strength and stiffness and is easily machined, fabricated, painted and glued.

Medical Market Usage

The following medical markets use Polyphenylene Oxide (PPO) Noryl®: Spine, Sports Medicine, Orthopedics, Medical Device, Drug Delivery, Pharmaceutical, Cardiovascular, Neurological, Analytical & Diagnostic.

Industry Suppliers and Trade Names

The suppliers we source Polyphenylene Oxide (PPO) Noryl® from are listed along with the trade names they use:

- Westlake Plastics Norylux (PPO)

- Ensinger TECANYL (PPO)

- Rochling SUSTAPPO (PPO)

Have Any Questions?

Please contact Vince Griffin, our Global Sales Manager for the Medical Plastics Division for more information on any of the products listed above or to get assistance on your next project:

office: 800.243.9696, Ext. 205

cell: 203.260.7738

email: vgriffin@modernplastics.com

Search Our Plastics Database

Learn more about our robust inventory of high performance plastics searchable by keyword, industry, manufacturer and shape.